|

|

|

|

|

|

|

|

|

|

|

|

MCS7001 is an

optimal machine for the test of various systems. This

machine record any measured value during the test of a system. The machine

measure and record also the real torque applied during any test. This is a

very important control for understand correctly the behavior of different

systems. For each

test are recorded all values, like the speed, the max torque, the times

required for each operation, the analogs inputs and so on. It is

possible also to record all measured values up to 100 times for second, and

display it graphically in order to see the exact behavior in a single test The test

is controlled with a PLC GE Fanuc, and the human interface is realized with a

Windows XP Computer. The

machine use digitals input/output to control pneumatic systems, sensors, electrical valves, etc. It control and

measure also analog signals for pressure, speed, vibration, temperatures,

etc. Our

brushless control system is very sophisticated and control any parameter for

each movement: position, speed, acceleration, torque limits, torque applied.

This

accessory concurs to carry out of the spins with a extensible ax. For

example it is used for the test of the locks mounted on doors or ante. The motor

controls the torque and the speed, executes test of 200.000 openings, and

graphically records all the data of the test.

Lock

mounted on test door. The motor develops torque until 25Nm, but it can also

limit the applied torque at 0.1 Nm. It

execute the tests of the lock and the handle, it execute the sequence of

necessary operations like: closing, opening with key, opening with handle,

release blocs, etc. |

|

Our experience The AUCO Italy has matured its experience in the tests on prototypes

with various companies in the arc of the last decades o f years. From the

axles for tractors with the Dana in the centers of Vimercate

(MI Italy) and in Arco di Trento (Italy), to the

tests of the new motors of the Tram for Alstom

France, at Sesto San Giovanni (MI Italy) and then still collaborations in the

realization of the equipments and the software of test of the electronics of Pendolino (the Italian super train), always with Alstom. In the field of the tests in production we have

realized systems for the control of the test islands, also with software

intelligent that speak the operating peoples, explaining the operations that

must execute in order to guide them in the various procedures. From these experiences we have realized various equipment of test,

also for the vibrations tests, preventive assistance of the problematic

mechanics, mathematical analysis of the vibrations in order to characterize

the parts that are near to the breach, safeguarding the prototype or allowing

however the preventive maintenance on the system. The MCS7001 is born from this experience and is studied in flexible

and simple way, rendering adapted it to many and many types of test. They is very simply to use, bat the acquisition concurs and the

control of the variable ones until 100 scansions to the second, controlling

whichever type of marks them and sensor standard. Software AUCO for the brush

less motors concurs to control them in a very simple way for the operator,

with commandos helps very clear. |

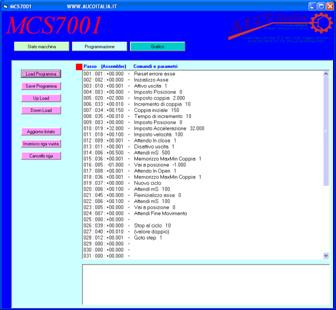

Software

The immediate commandos allow you

to try the test manually, and also to carry out single tests in order to

verify the behavior of the system to test. After to have defined the sequence

of operations, they can be inserted in the test program. The commandos are

very simple, well described in the help automatically always visible

The commandos are very simple. The

software is developed from AUCO Italia and so you can ask as any

modification. So, any application become for us a possibility to create new

commandos and new functionality, and so our software become more and more

flexible and adherent to the various client requirements. A specific program for the

software modernization concurs with all the customers to have use of the new

functionalities |

Characteristics The MCS7001 is the new series of

testing machine. The electronics are based on three levels. The electronics

of engine control, the PLC of management of the test and for the acquisition

and the control of all the variable, and the computer for the supervision,

the recording and the operating interface. All it is enclosed in a structure

of reduced dimensions, easy to move inside your tests area. The machine is personalized on

the requirements of the customer, its characteristics of base are:

It is open to the DCS world, in direction of high level for business

nets, DCS, SCADA, etc, and also in direction of field for distributed

controls, Azardus Area controls, in observance of

all the emergency norms up to zone 0. |

|

Up

grade possibility In the structure is predisposed

the space for 20 input/output cards and 4 brush less drives. As an example it is possible to installe: 32 input for extensometers/cargo cells, 12

input PT100, 16 input thermocouples, 8 analogic

output, 8 analogic input, 4 motors brush less

control, controlled also in torque, 64 digital input, 32 digital output. We

can realize also solutions whit a greater density and the same dimensions of

the structure. |

The

various accessories can be placed inside the machine, so the machine is very

compact and easy to be moved. The connections whit the test equipment are

realized whit multipolar standards connector, so

the passage from a test to an other is very easy.

There are machine MCS7001 that can be used on various equipments of test,

also at the same time. We can realize different equipments in order

to satisfy any requirements of the customer. The system is flexible and expandible in any moment. We have versions also with four

brushless motors. The software is simple and of immediate use. All the recorded data are

exportable graphically and in Excel format. |

Connectivity and teleassistance The system is equipped whit a

1GBps Ethernet card. Possibility of wire-less cards, connectivity via modem,

ADSL, GSM, GPRS, UMTS, SUPER UMTS. For the areas without field we

supply the connectivity on a Immarsat channel on a

network of satellites active on all planet, whit exclusion of only the

icecaps. The

offered connectivity will concur you to manage your system from whichever

emplacement of your business net and to have, upon request, our tele-assistance on all the planet. |

|

|

|

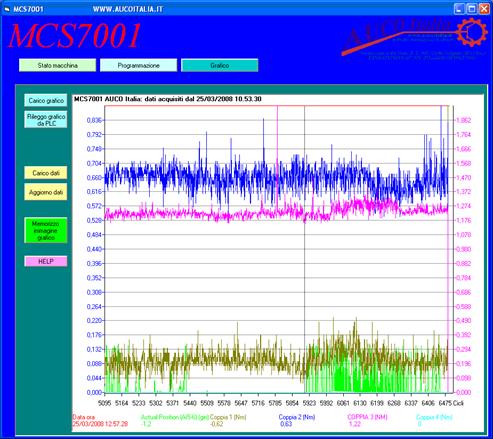

Single

test diagrams During the single test

can be recorded all data of the variable, with a frequencies up to 100 times

for each second. The data come

transferred on the PC automatically and are immediately visible. In the diagram to the

left the you can see the torque applied on the key

for open the door, at the instant 2,9.

The system applied one increasing torque

until the door open. The position can be noticed (blue line, scale of left

with thousand division of turn) that for 0.6 second remains stationary until

increasing the torque comes (pink line, scale of right with thousand division

of Nm). You notice that in the

moment in which the mechanism unlock the door, where there ise a negative peak of speed (blue line) the system

succeeds however to maintain the control of perfectly constant torque in its

increment, in accord whit established how much in the test. This is important

when you must to observe a exact increment of torque as an example, for the

test of emergency exit. where the forces must be increased in accord whit

specific norms. The single test

diagrams can be recorded automatically every enne

test, or to forehead of an alarm, or forehead of a particular event, like a

problem in the tested system. |

|

|

|

Sequence

test diagrams The test of a equipment

can last little moments or also various months. The system acquires all

the important data of every single executed test and it introduces them in

graphical shape concurring with the operator to understand immediately as the

test is proceeding, visualizing eventual variations in the time of some

important parameters, like the torque applied in a important movement, the

mechanical strech of particular, the temperature of a point of the system, or

the vibrations that are generated in a particular movement. The data are readable

with whichever database or mathematic software. On machine MCS7001 they

come visualizes to you in simple and immediate way. The diagram is

immediately visible without necessity of modification. They are available

functions of zoom in and zoom out, pan, numerical reading of the values,

activation grill with selected scale to right and on the left of the variable

ones. The data are exportable

in graphical format and text, for the

entire test and also for the diagram like is visualized. |

|

|

Distributed Control System For the

control of great amounts of signal we realize systems whit DCS technology,

applied also in zones to high risk of outbreak. As an example in the refinery

of Skikda (Algeria) during 2004 we have realized a installation for the

control of 1000 temperatures (500 installed), with a system distributed in

azardus areas, redundancy 2 on all the levels. With a

simple communication cable and a power

cable all the field sensors and the field actuators are, also at a distance

of some thousand of meters. The system is up gradable practically in

limitless way. |

Availability

The system is available in 16 weeks from the

order, the price is very interesting. The standard system, like

described, comes proposed at 38.000,00 Euro, included installation, personal

instruction and a simple custom request. Guarantee for two years included. (+ tax and shipping). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|